Today, we are facing two modern problems “plastic pollution” and “greenhouse gases”, but now the new solution proposed by American scientists can solve the two century problems at the same time.

The eternal plastic has always been a headache for all countries. Those plastic products, big or small, will become smaller fragments after experiencing wind, ocean, and even ultraviolet rays, and eventually become invisible microplastics, making them invisible to the naked eye.

It is difficult for scientists to track the flow of plastics flowing into nature. On the other hand, modern convenience is also accompanied by a large amount of man-made carbon dioxide emissions, such as fuel vehicles, thermal power plants, etc., which will increase the greenhouse gas and evolve into an intractable global warming phenomenon.

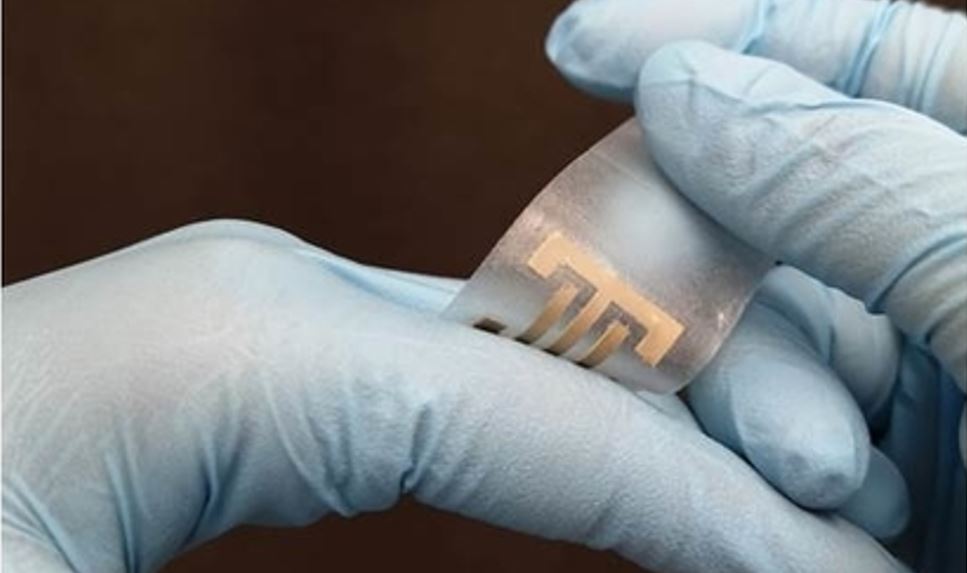

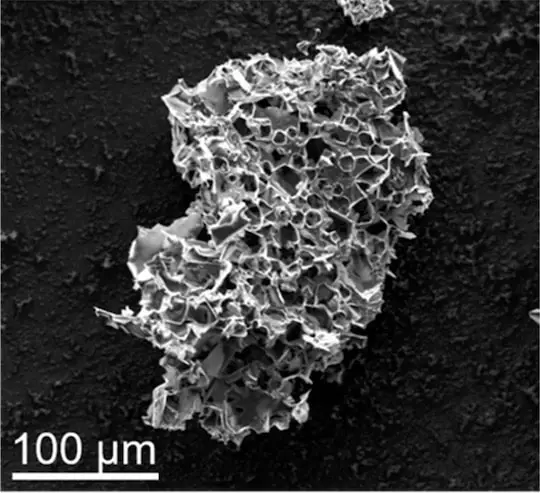

However, Rice University in the United States has now proposed a solution that kills two birds with one stone. As long as the plastic is placed at a temperature of 600 ºC for 45 minutes through thermal cracking technology, the plastic powder can be converted into particles with nanopores, which can effectively absorb carbon dioxide in the air.

How to Store Carbon to Plactics

Usually at room temperature, each plastic particle can permanently store 18% of its own weight of carbon dioxide. After heating to 75ºC, it can release carbon dioxide, and 90% of the pores will open again.

The team pointed out that this is a reusable product. Adsorbent particles can also be used in fuels or building materials. As a by-product, the process also produces “waxes” used in detergents and lubricants, which are widely used.

The team pointed out that although common polypropylene (PP) or polyethylene (PE) plastics are difficult to recycle, they are actually very suitable for conversion into detection and capture particles.

The scientific team estimates that the cost of installing new carbon capture equipment in pipelines will fall at about $21 per ton, compared with the current power plant’s flue exhaust carbon dioxide capture, which mainly uses compound amines, which costs as high as $80 to $160 per ton /dollar, the new material is not only cheaper but also lasts longer.

Rice University chemist James Tour said that in the future, carbon dioxide emission sources such as flue exhaust may be equipped with new waste plastic-derived materials, which can solve the plastic problem on the one hand, and also deal with carbon dioxide emissions.