It is not without reason why plastic is called 10,000-year-old garbage, and different types of plastic make it difficult for people to recycle efficiently.

Now a new catalyst developed by the MIT team can decompose mixed plastics into “propane”, which is a good way to burn fuel or to make new plastics. Although plastic is convenient, it is an indispensable item in daily life.

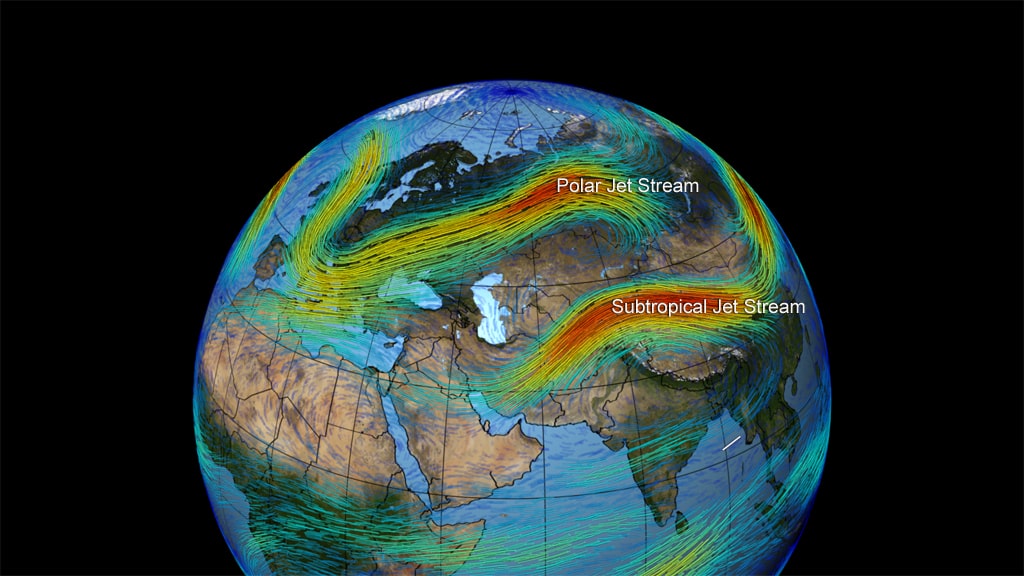

However, due to random littering and ineffective recycling, plastic footprints are all over the world today, from the North Pole to the South Pole, the deep sea to the top of Mount Everest, and microplastics can be found in all kinds of organisms, including humans.

Plastic has very strong carbon bonds, so it can maintain excellent elasticity and stability during use, but this makes the recycling process difficult.

To make matters worse, different types of plastic require different recycling methods, making it difficult to sort and recycle on a large scale.

The new technology proposed by the MIT team can process multiple plastics mixed together, converting them into a single product, propane.

Propane itself has a variety of uses, from being used as a fuel for engines, barbecues and home heating systems, or as a raw material for new plastics.

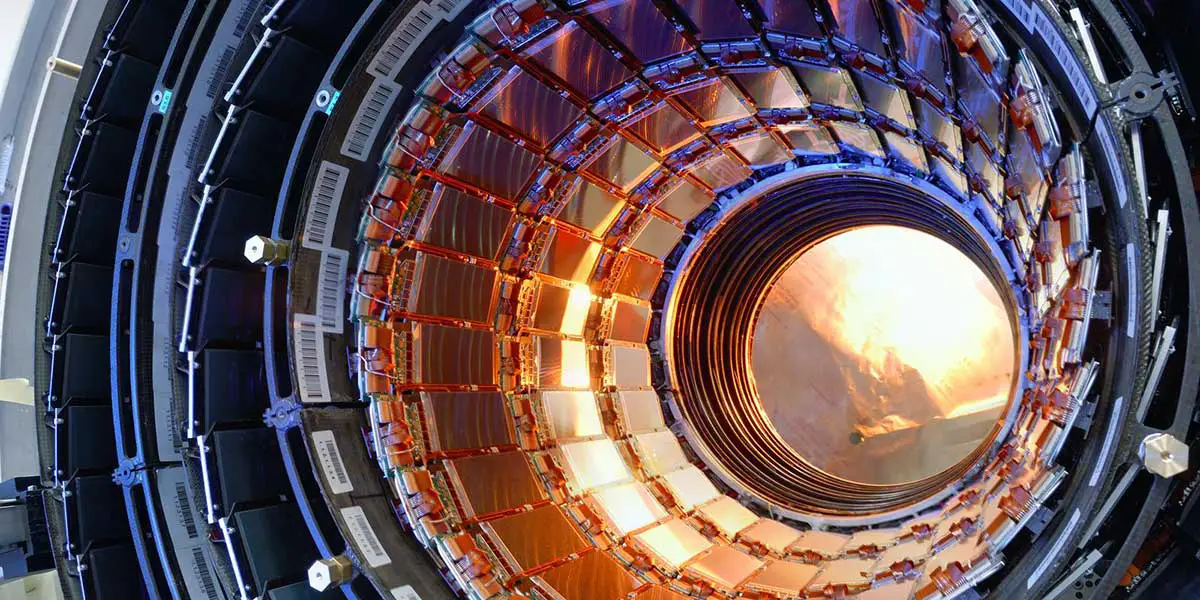

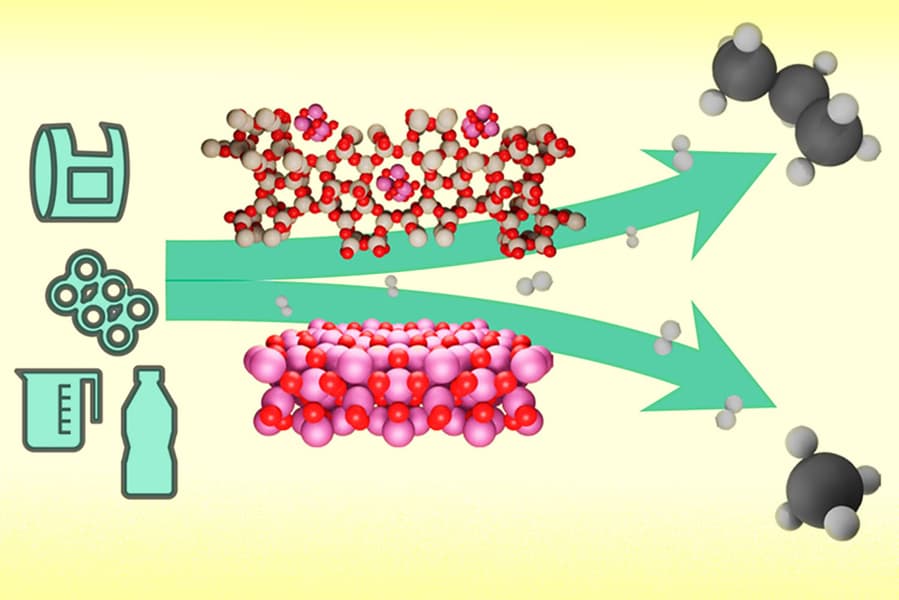

The catalyst developed by MIT is composed of porous crystalline zeolite, in which the team also filled the zeolite with cobalt nanoparticles.

While other catalysts can also randomly break carbon bonds, resulting in different end products, the new catalyst breaks carbon bonds at specific and repeatable locations that are more predictable and controllable.

The new catalyst is also suitable for many types of plastics, including the most commonly used polyethylene (PET) and polypropylene (PP).

After actually testing the mixed plastic experiment, the team also found that the catalyst can convert about 80% of the plastic into propane without producing by-products such as methane.

The resulting propane can be used directly as a low environmental impact fuel or used in closed loop systems to make new plastic feedstocks.

Importantly, new catalyst feedstocks such as zeolite, cobalt and hydrogen are relatively inexpensive and readily available.

But the team also pointed out that while the research is interesting, how to scale up the technology and then actually use it in the real world is also a challenge, and whether it will be affected by glue and labels.